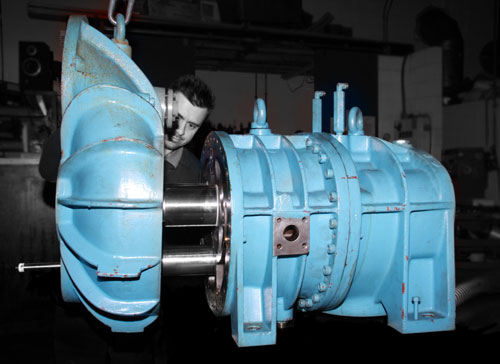

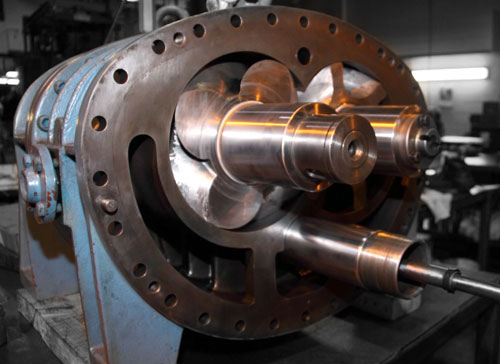

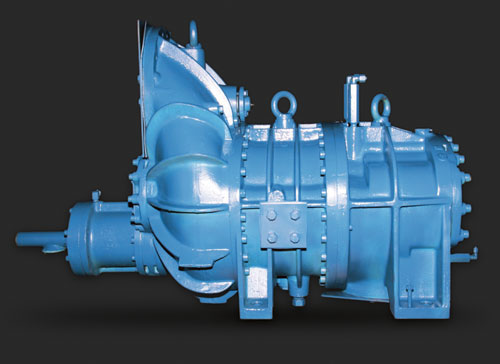

Remanufactured Compressors

All compressors remanufactured by Comptec go through a rigorous remanufacturing process (see below) to ensure that they are delivered to the customer in ‘as good as new’ condition, whilst providing substantial cost savings. We remanufacture all types of commercial and industrial compressors, including fully hermetic, semi hermetic, scroll and screw, with all parts of our remanufacturing process being undertaken in our specialist, in-house facilities in the West Midlands.